I love Home Depot. It’s great for all my projects. I’ve spend a lot of time lately trying to find a simple toggle switch that can handle up to 5 Amps. I finally found one I liked that’s about $6 a piece and was about to order some, but held off. Then I stopped by Home Depot just to get some PVC to wind an electromagnet around. I figured I’d look through the electronics isle just in case they had a switch. Suddenly, inspiration struck! A cheap switch that can handle at least 5 A? A light switch of course–for only 69 cents!!:

Okay, it does say 15A 120 VAC only, but I assume that will also work fine with <12 VDC @ 5 A. I did also pick up a 1/2″ PVC pipe so I could start on my first electromagnet.

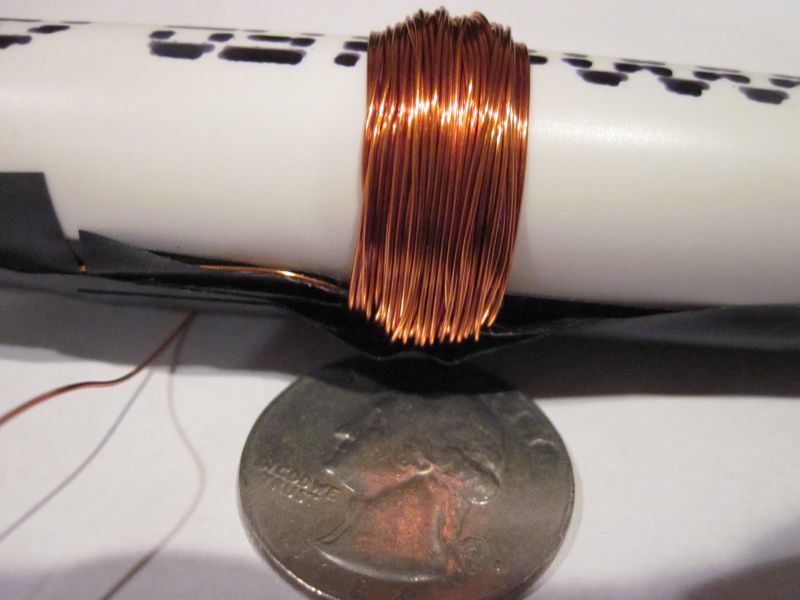

My goal was to use 26 AWG wire, 13 turns per layer (to make a coil 1/4″ long) and 10 layers. As it turns out, winding these is rather difficult, especially without a form. I tried to wind it close to the edge of the pipe so I could see if a 1/2″ ball bearing could be picked up by it, but I couldn’t get enough tape on the edge to keep everything from falling apart. So, I decided to wind it further up the pipe so I could use a lot more tape. Without any side pieces to hold the shape, it’s difficult to get each layer of wires to stack on the previous. But I did eventually get approximately 5 layers done:

Figure that’s good enough for now, so I’ll see what it can do. I did a quick test with the meter to find about 1.8 Ohm resistance. Since that’s not going to limit the current much, I didn’t want to try it with a real power supply and instead started with a 9V battery. I got some sparks off it, so I went for a magnetic test. Placed my ball bearing close to it and did see it move! Not far or far, but it did move. I tried putting the ball bearing inside the PVC, as my current goal is to hold it in there. That test failed though. I couldn’t get the ball in the right position at the same time as keeping the the power on to the coil. And, of course, one problem with a PVC pipe is that it’s not transparent, so I can’t see what’s going on inside. One of my next goals is to find something I can see inside of for this… I wish I had been able to wind the coil closer to the end of the pipe so I could try sucking the ball bearing into it. Maybe after I work on my winding technique, I can try that again later.