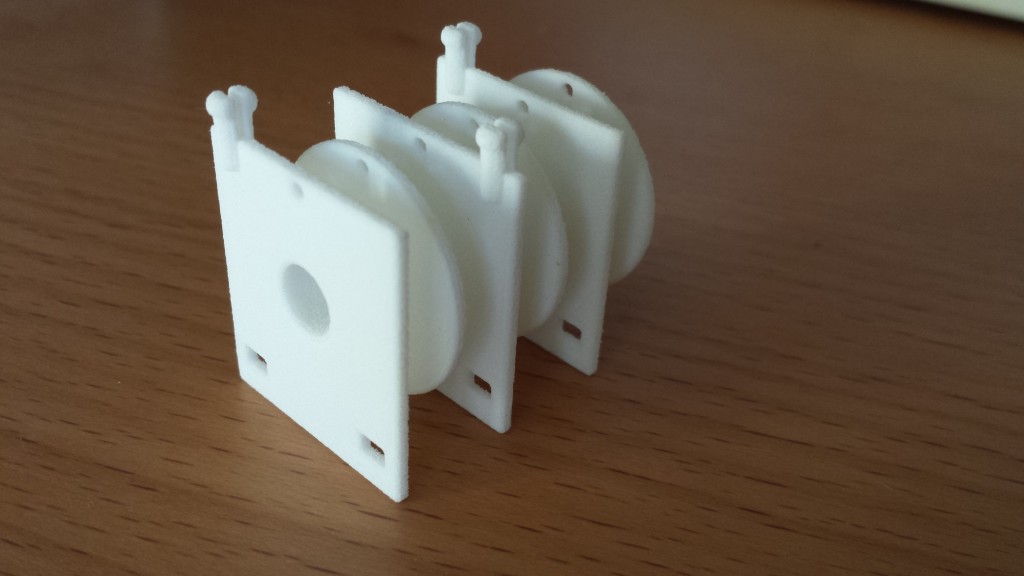

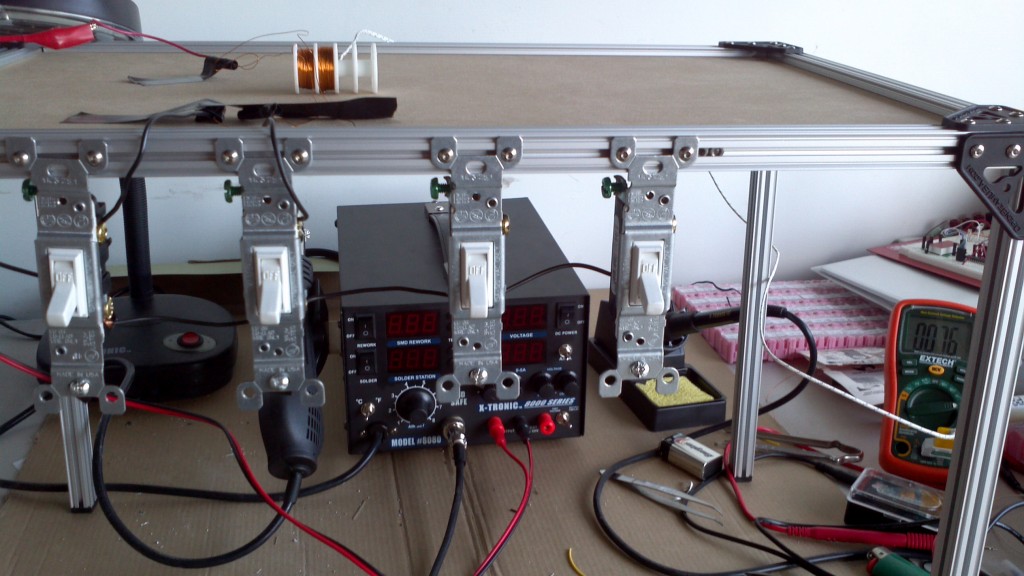

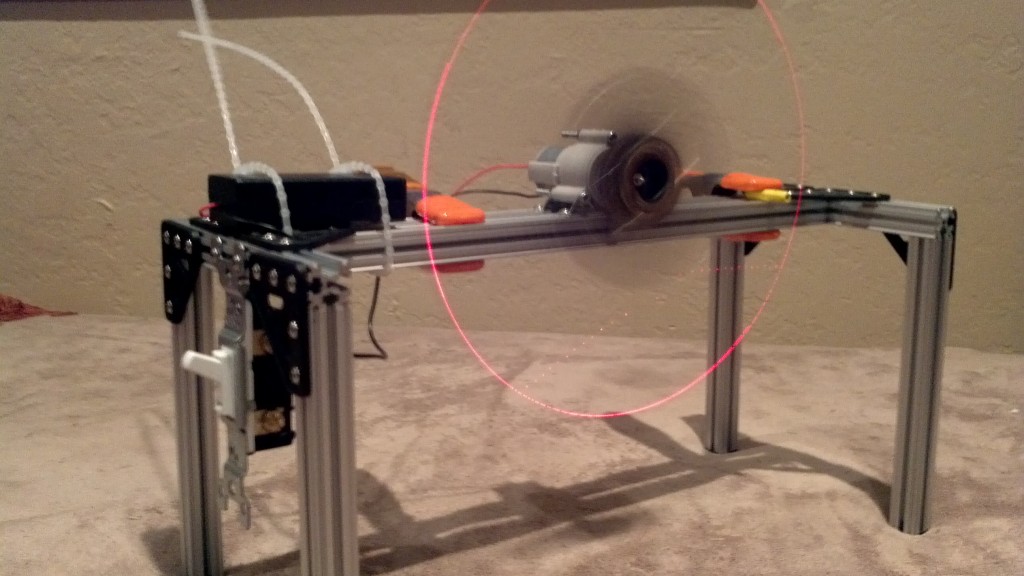

Since it will be a while before my new coil design is ready, I took the take to get my test platform setup:

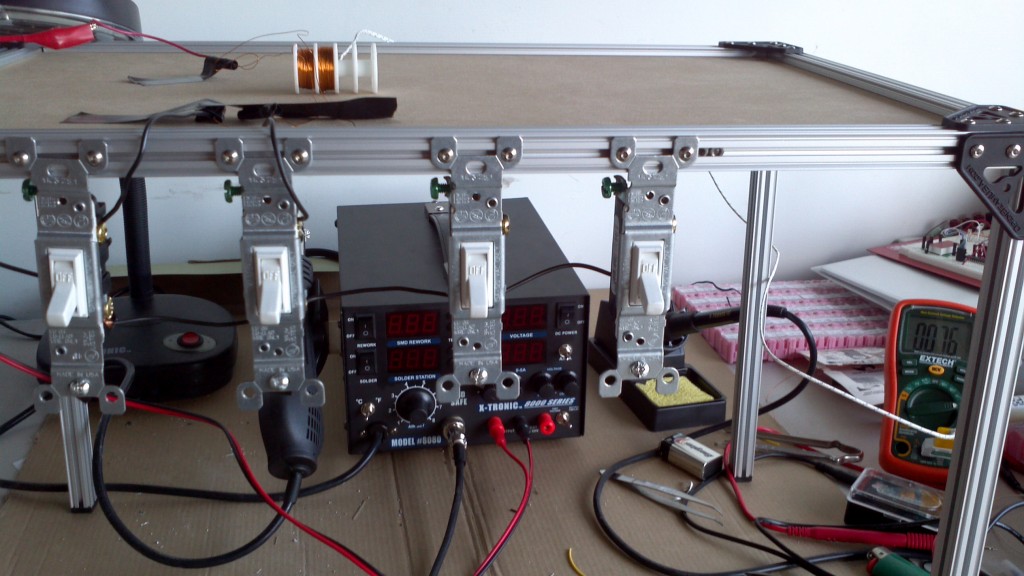

This gives me a switch so I can turn each coil on and off independently. It also lets me turn them all off and adjust the voltage accurately before applying power to the coils again.

Just like on my spinner platform, these switches made things work much better! I don’t have the coil secured (waiting on my new coil design with mounting points for that), but I was still able to learn some things.

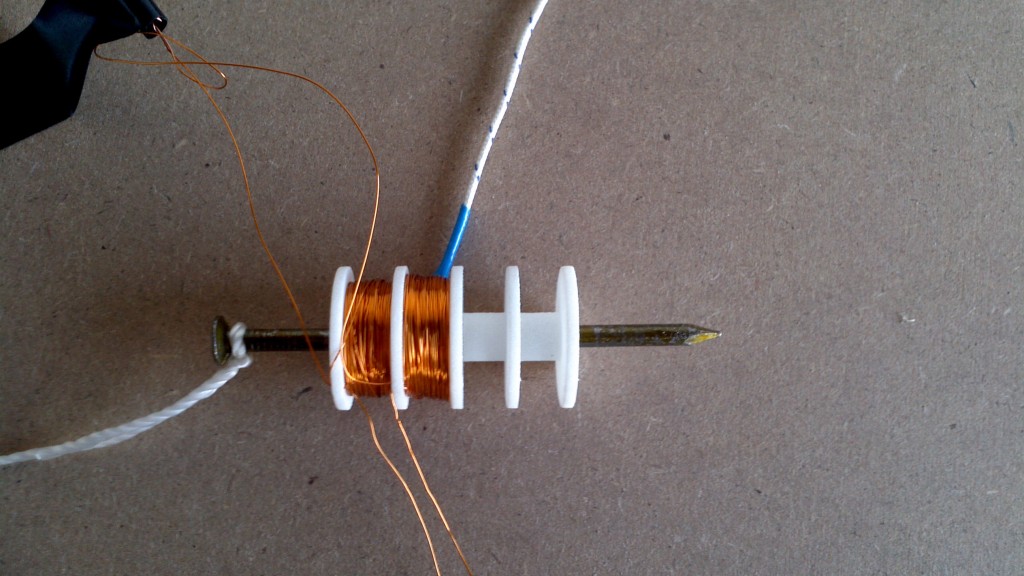

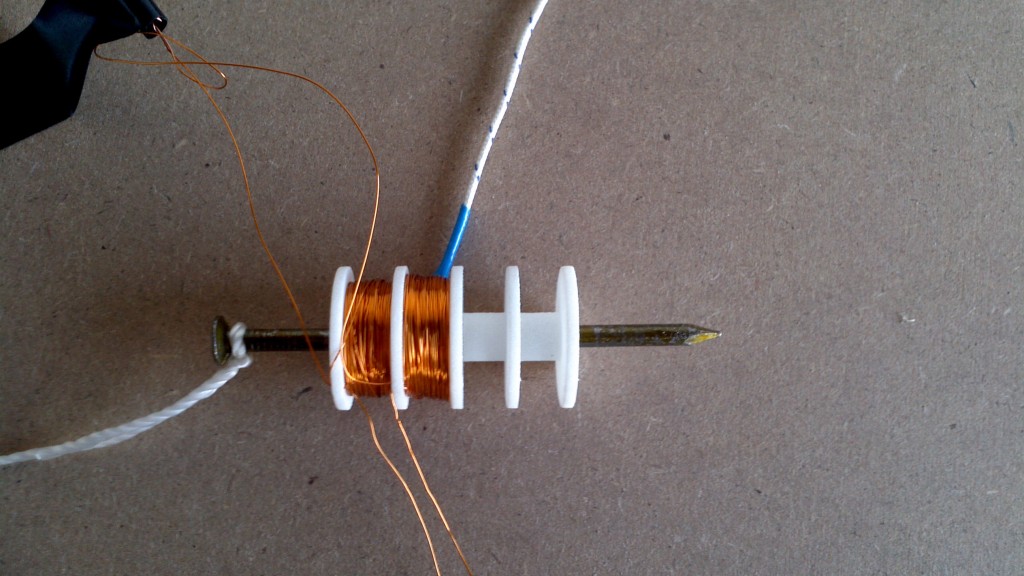

First, using the coil that is slightly larger than the other, I did tests to see how much current I can push through there. And again I kept my temperature probe on the coil so I could monitor if it was getting too hot. Better picture here:

I ended up with this:

| 5V |

10V |

12V |

15V |

20V |

|---|

| 0.64A (84°F) |

1.25A (100°F) |

1.40A (120°F) |

1.60+A (HOT) |

2.0+A (170+°F) |

My notes from things I tested:

- Switching between the two coils, I was unable to get the nail to move back and forth, no matter what voltage I used. (I later learned this may be due to the length of the nail.)

- It takes a long time for the coils to cool. Even brief pulses at 15V cause the temperature to shoot up to 130°.

- I tried using a scale to measure how much force the electromagnet exerts. Most of the tests, I got absolutely nothing. While playing with 20V, I noticed that I got a strong pull right when the end of the nail was coming out of the coil. I measured that at 60 grams. (I’m not sure what force that is–I suppose the equivalent force that it takes to pull 60 grams against gravity.)

- At 10V, there is no noticeable pull on the nail. I’m not sure how little I can feel, but I’m sure this is quite light.

Checking in with the Shapeways design specs, I see that the flexible plastic is only heatproof to 176°F. This is clearly a problem as it quickly gets that hot at the minimum voltage that I felt a significant pull.

I need to try either other wire sizes, better heat sinking materials, or a different design.