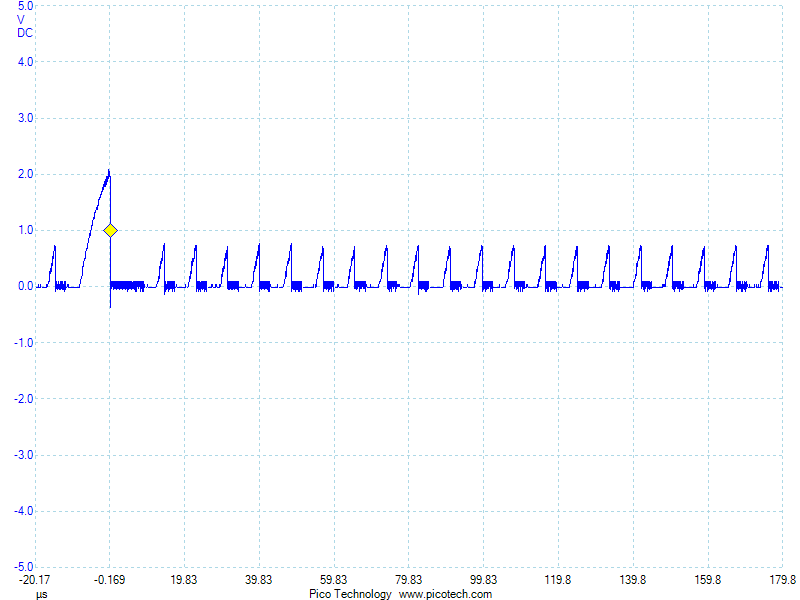

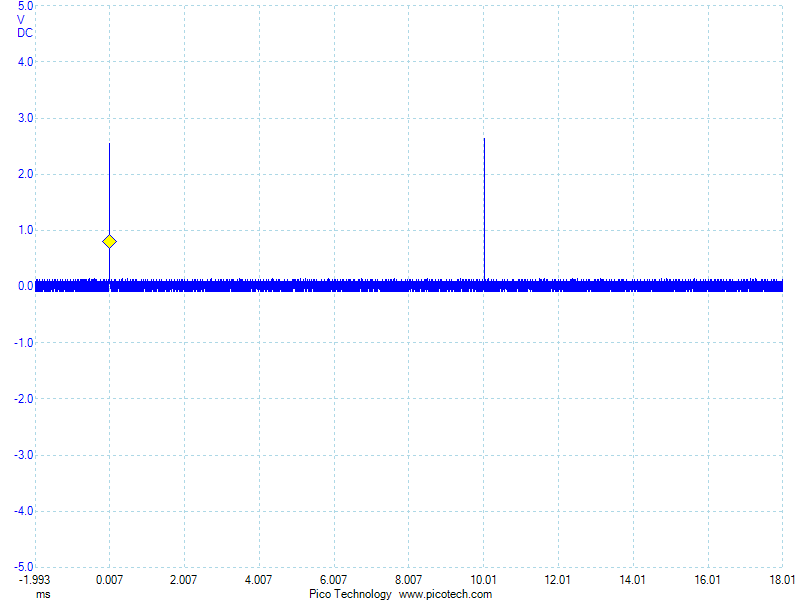

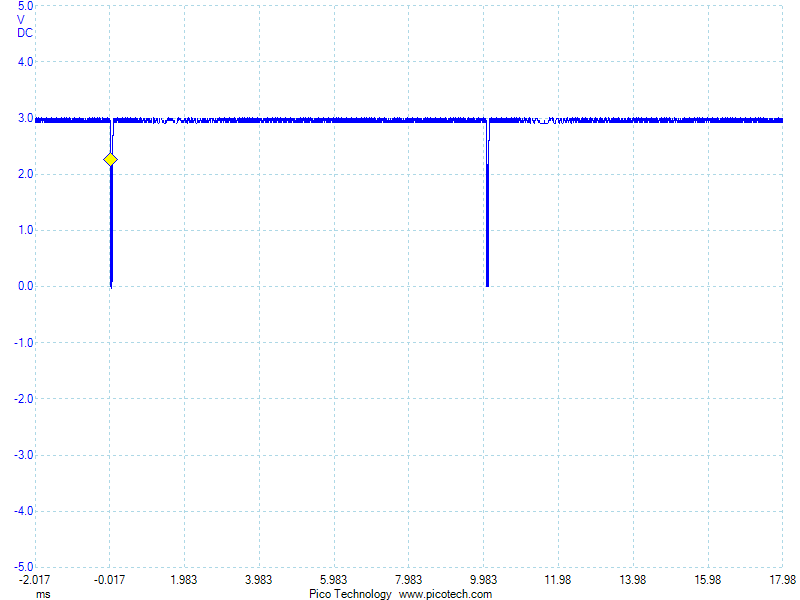

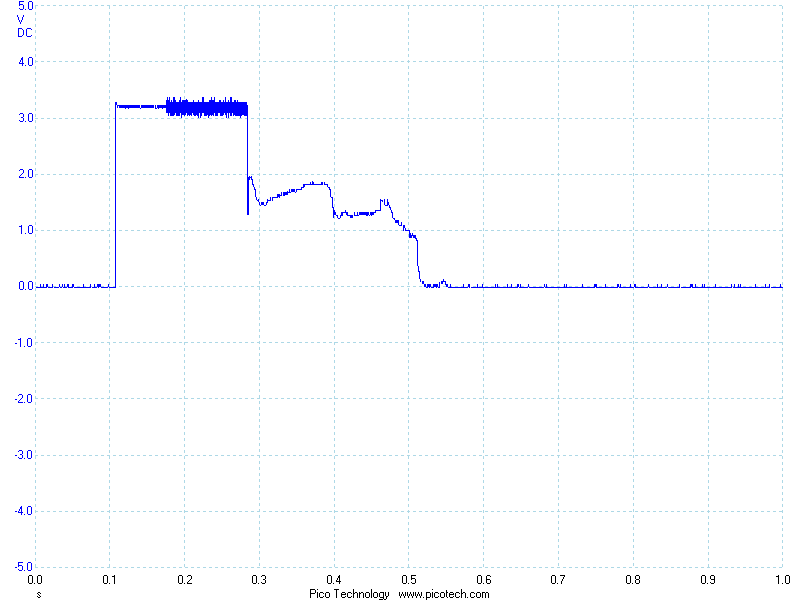

I figured that even if the hall effect sensor glitches when switching a bunch of LEDs in the presence of a magnetic field, I could still make use of this board by not switching anything while the hall effect sensor is active. So I changed the code to display a binary pattern. When the hall effect interrupt is triggered, hold the current LED display for 1 ms to give the board time to spin past the magnet, then reset the pattern to 0.

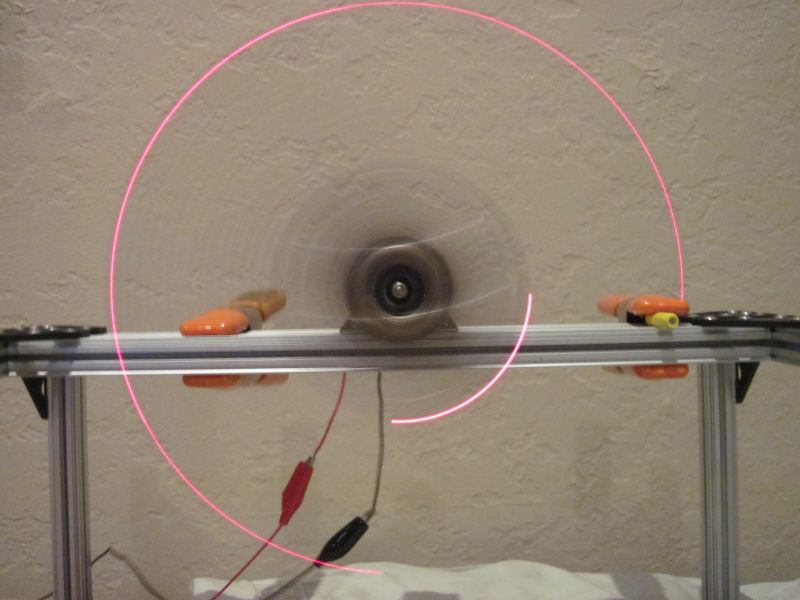

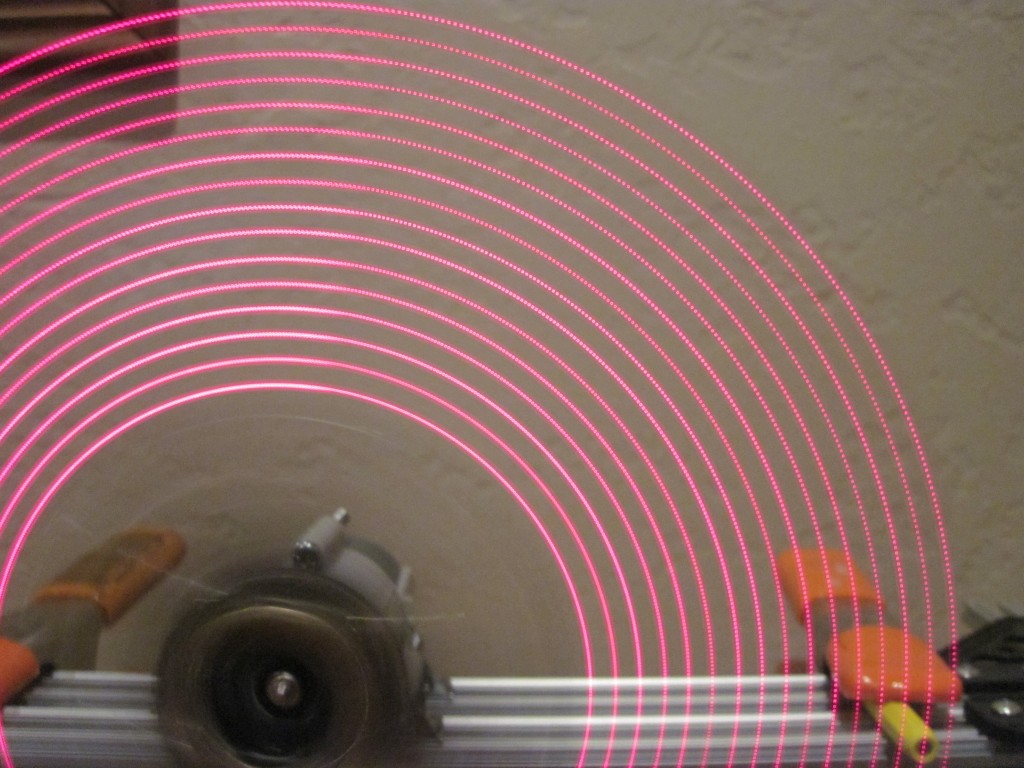

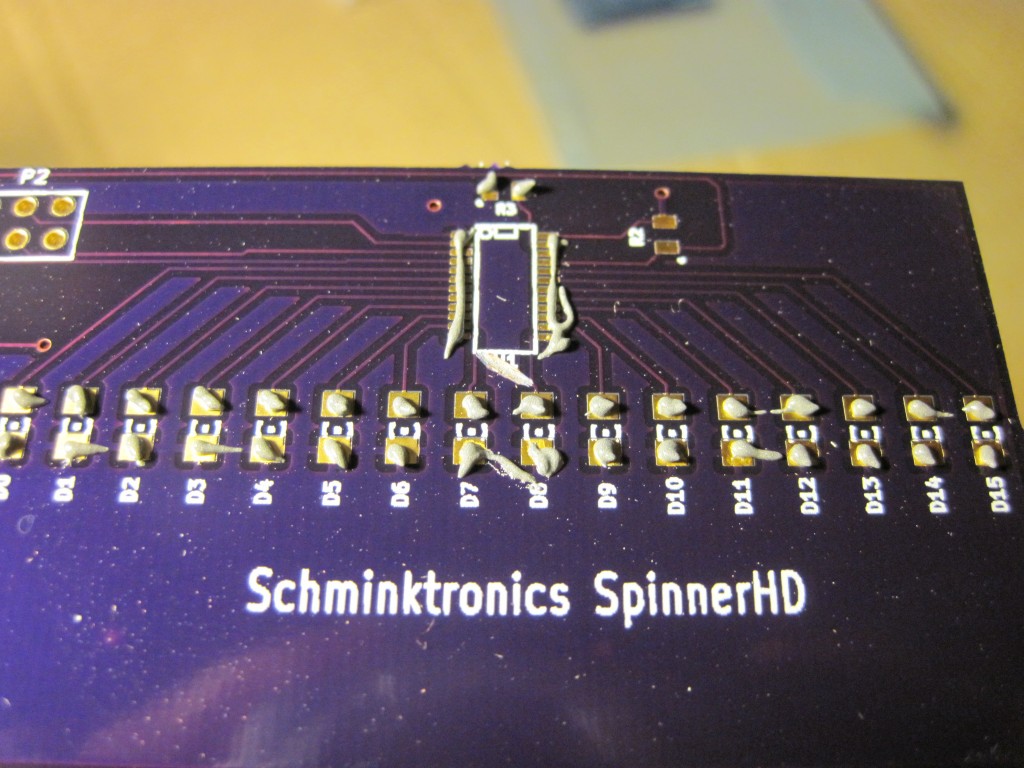

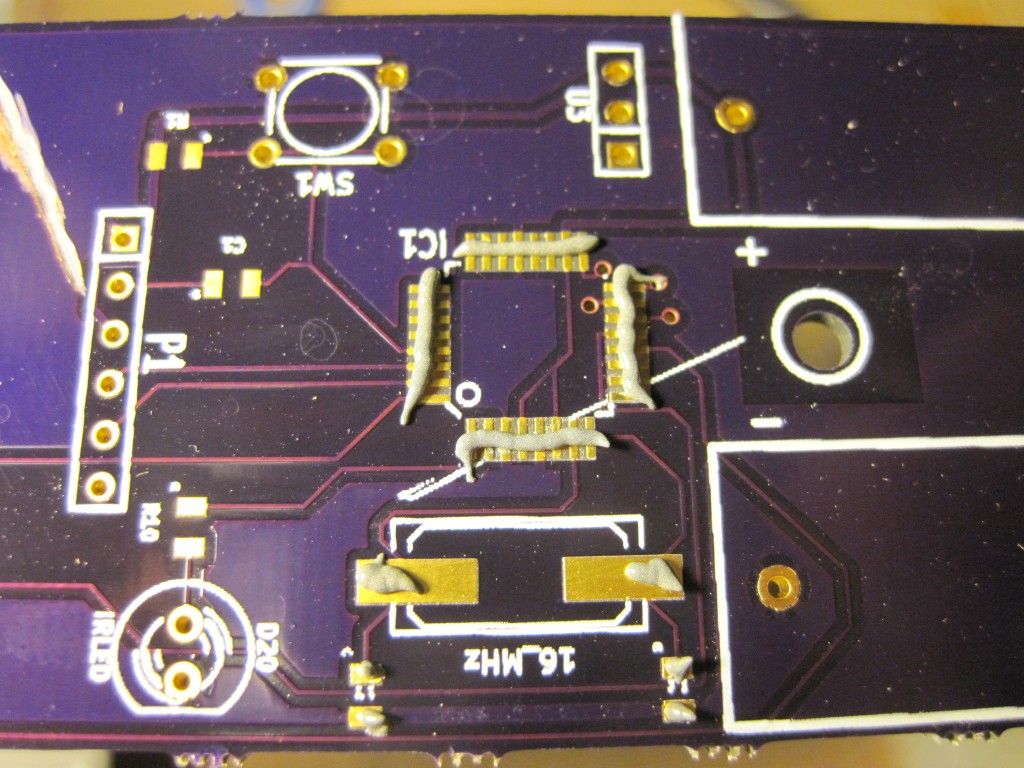

As soon as I turned on the board, I could tell there was a problem. No more than 6 LEDs ever lit up, even with no magnet to reset the pattern. But, all the LEDs that were flashing were going too fast to clearly see what was happening so I spun it around to see what it looked like:

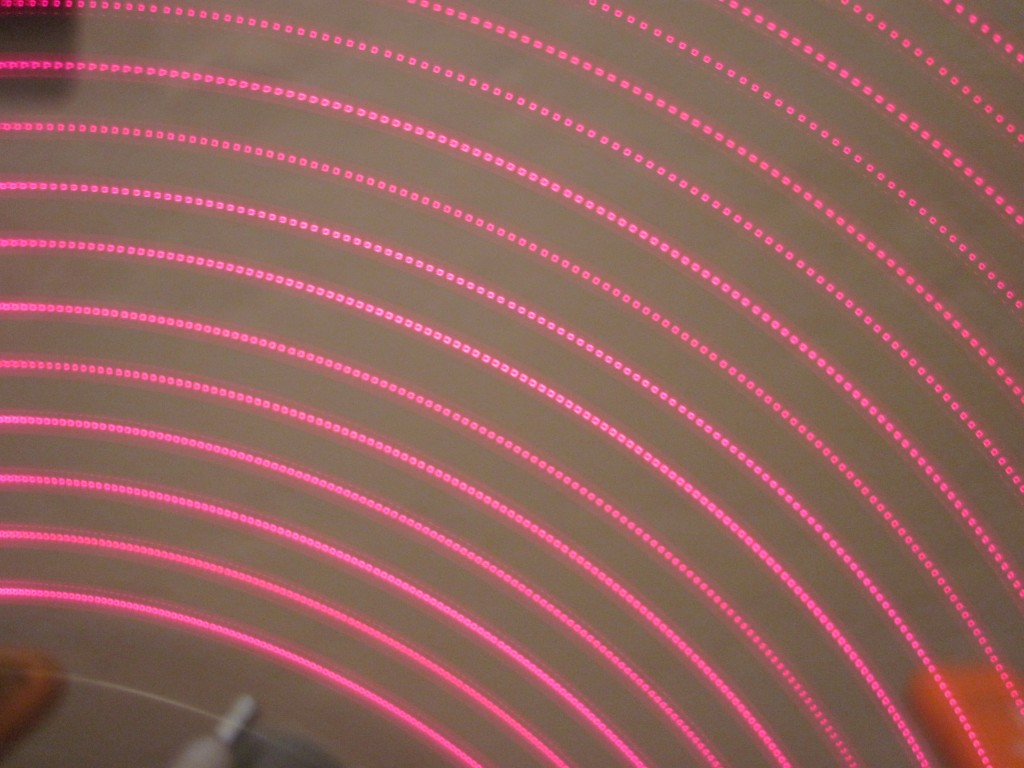

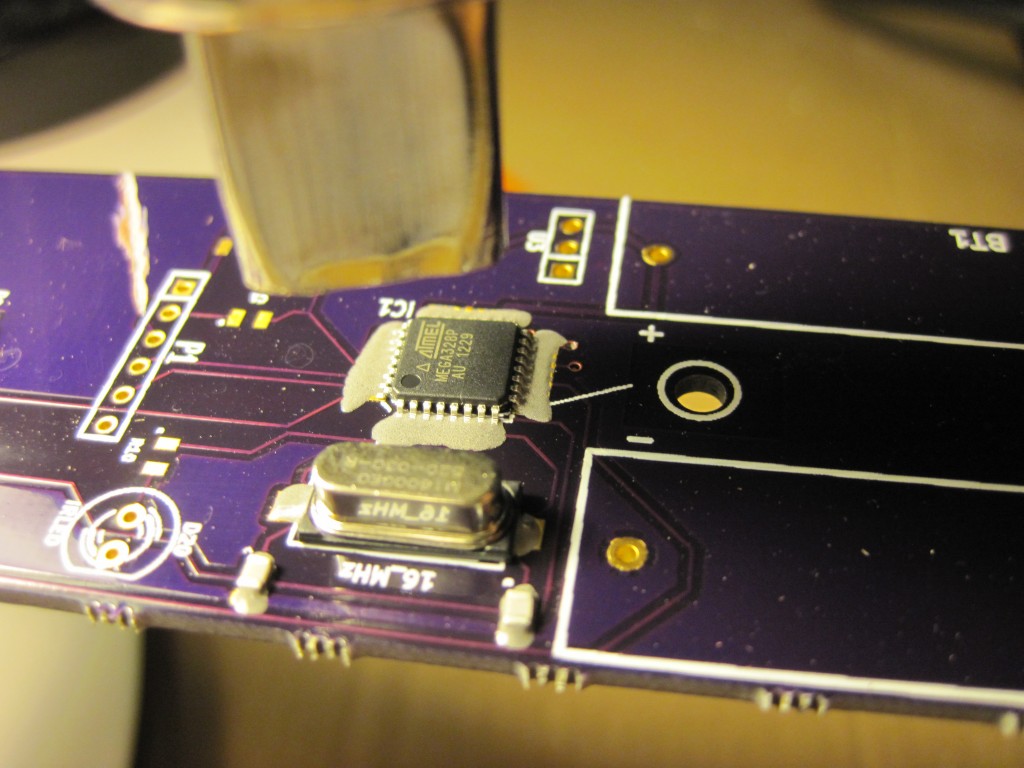

Once again, I am impressed by how fast I can switch the LEDs and how small they appear when I do. (Look at the outer most LED–you may have to view the full size image to even see the individual pixels.)

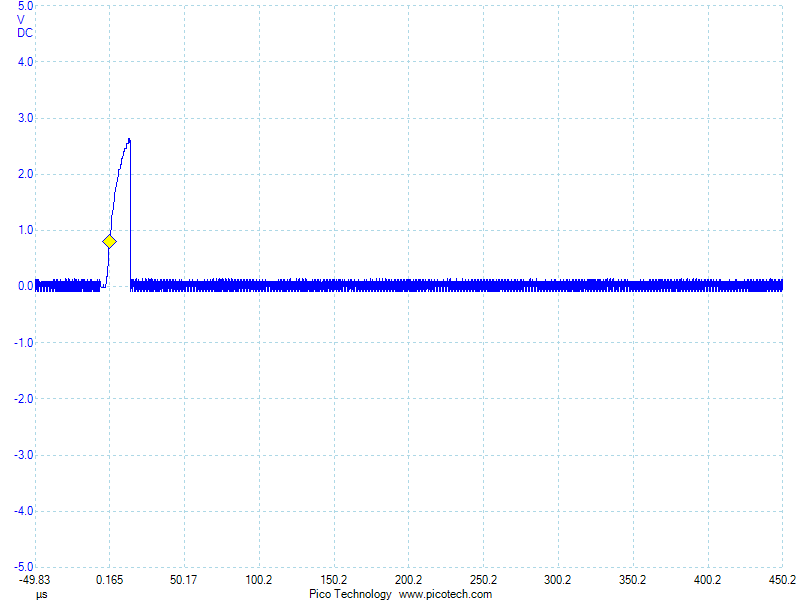

But from this, I can see what’s happening. Each time I have 5 LEDs on, then switch them all off (and in this case, switch one more on), I get a false hall effect pulse. This is seen in the pictures by the single LED holding for 1 ms, then resetting back to the beginning of the pattern.

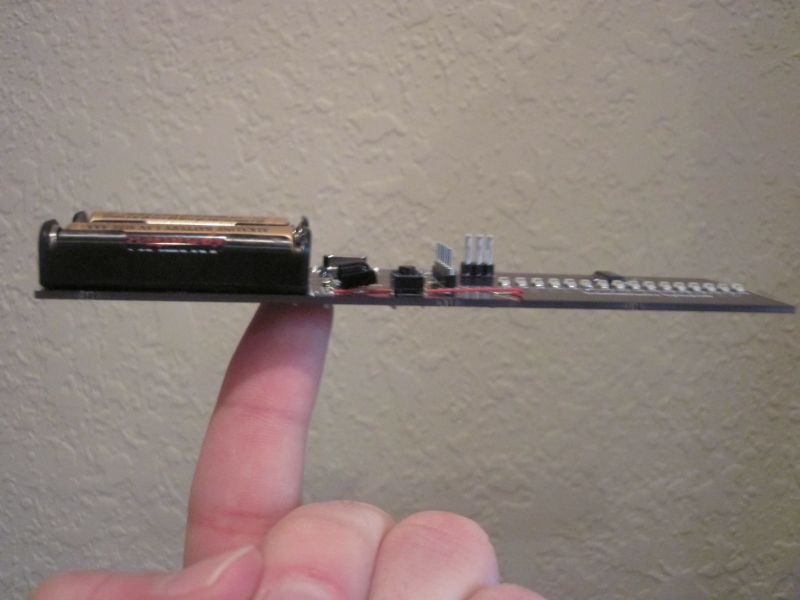

So, I can’t really do anything interesting with the board until I fix this problem with the current. My first attempt at putting on some filter caps failed, so I need to find a better way to do it or work on another board design that has the filter caps included in the layout.